Pulp Maceration For Healthcare: The DDC Dolphin Difference

NHS England's 2011 survey on healthcare-associated infections and antimicrobial use estimated that 300,000 patients a year in England acquire a healthcare‑associated infection as a result of care within the NHS[i].

At DDC Dolphin, we have developed our pioneering range of Pulpmatic medical pulp macerators to help combat HCAIs, protect health and save lives.

Accessibility Controls

The player supports TAB to change the controls.

Update Required<br/>To play the media you will need to either update your browser to a recent version or update your <a href='https://get.adobe.com/flashplayer/' target='_blank'>Flash plugin</a>.

ARRANGE A FREE TRIAL TODAY

What Is A Pulp Macerator?

Pulp macerators are machines which pulverise and dispose of single-use medical pulp containers and human waste.

The technology of choice for thousands of healthcare facilities around the world, a macerator is a fast and safe human waste disposal solution, providing a safe and efficient alternative to washing bedpans by hand, or using a washer disinfector.

Macerators are opened and closed using hands-free technology. This allows a pulp container - along with its contents – to be placed inside the machine without the need to wash or dispose of items elsewhere. Once the lid is closed, the maceration cycle will be complete in as little as 65 seconds – giving your staff much more time to care for your patients or care home residents.

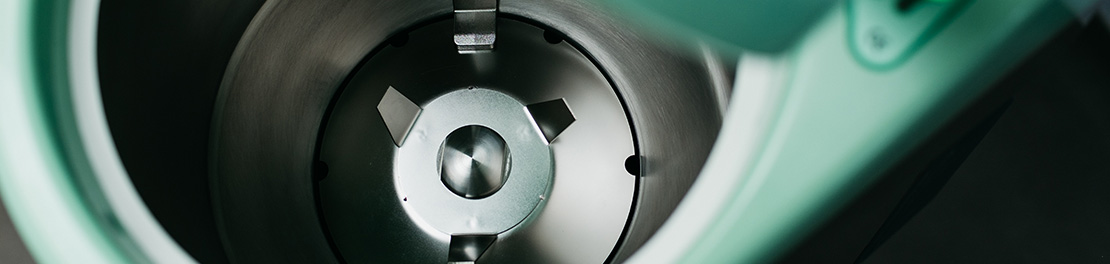

During the maceration process, the pulp container and its contents are quickly and effectively pulverised into a watery slurry, using high speed rotating blades. The slurry is discharged into the main sewage system, similar to a conventional toilet.

The COVID-19 pandemic sparked a ‘new normal’ for healthcare. Learn more about futureproofing your sluice room here.

Why Are DDC Dolphin Pulpmatic Macerators Different?

DDC Dolphin’s range of Pulpmatic macerators underpin the infection control strategy of thousands of facilities around the world.

Our innovative and unique technology is showcased across three market-leading models – Pulpmatic Uno, Pulpmatic Ultima and Pulpmatic Eco+.

Each model is specifically designed and built to serve a host of needs across the healthcare sector.

You can expect:

- The most environmentally friendly, economical and hygienic macerator technology on the market

- Large capacity machines, disposing of up to six items per cycle

- Quick maceration cycles from just 65 seconds

- MicrobeSafe+ antimicrobial technology in polymer surfaces, featuring antimicrobial and antifungal additives to stop the growth of harmful bacteria

- Low water consumption, from 9.5litres per cycle

- Completely contactless operation, reducing the risk of cross-contamination

- Continuous, free-flowing output of waste to drain, through DDC Dolphin’s advanced open flow maceration technology

- High quality materials and components, including high grade stainless steel

- Automatic drain flush, which can be programmed during low use times to limit the build-up of stagnant water and remove the possibility of Legionnaires’ disease

- Various start options to suit each facility’s requirements, ranging from self to auto start

- Reduced operating noise, with advanced materials to absorb energy for quieter operating noise

- Audio annunciation – helpful voice guidance available in any language, decreasing costly training requirements and reducing the number of staff errors.

We can help you make tax savings on your sluice room purchases. Contact us now to find out how.

Pulpmatic User Benefits

Patient health and quality of care pivots on the effectiveness of clinicians and caregiving teams. That’s why every Pulpmatic macerator is built to maximise user efficiency and safety, equipping clinicians with the technology they need to provide exceptional care.

Hands-Free, Hygienic Operation

In healthcare settings, cross-contamination can be fatal.

The World Health Organisation report that HCAIs annually account for 37,000 attributable deaths in Europe and potentially many more that could be related, as well as 99,000 deaths in the USA[ii].

Major effort has, therefore, been put into improving hand hygiene standards for healthcare providers to manage hospital internal sources of contamination[iii].

Every Pulpmatic macerator is built with hands-free operation, including foot cup opening and auto close functionality. Not only will this save time for busy clinicians, but it will ensure that human waste disposal is kept free of unnecessary touch points that allow bacteria to spread.

Reliability You Can Depend On

If sluice room machinery breaks down, there’s a lot at stake. The safety and efficiency of your clinicians, as well as the health of your patients, could be negatively impacted.

Pulpmatic macerators incorporate pioneering technology to prevent machine downtime because of user error.

Clinicians will find the Eco+ easy and intuitive to use, thanks to a one-of-a-kind, 5-inch LCD antimicrobial screen, which guides the user through the status of a maceration cycle, correct items to load, cycle time remaining and, when required, error information. These visual instructions will overcome language barriers and prevent breakdowns through accidental misuse.

In addition, every Pulpmatic can take advantage of unique, customisable audio annunciation in any language, providing an additional layer of support for clinicians and reducing costly training requirements.

Prioritise Patient Comfort With Quiet Confidence

A calm environment can be key to recovery.

Complete with bespoke noise reduction, Pulpmatic macerators are versatile enough to be installed where you need them most - including small wards, isolation rooms and en-suite bathrooms.

Furthermore, advanced materials absorb energy for quieter operating noise.

Infection control precautions can have a seemingly unavoidable impact on the time that can be spent at the bedside of patients. Read our advice on giving time back to hands-on care.

Pulpmatic Infection Control Strengths

Easy Clean Surfaces and Antimicrobial Technology

MicrobeSafe+ is an antimicrobial additive with a powerful antifungal accompaniment.

When a microbe lands on a surface which is impregnated with MicrobeSafe+, the microbe is destroyed or damaged, rendering it unable to reproduce. Its use can therefore reduce the spread of HCAIs by eliminating cross-contamination routes. This is particularly effective in the sluice room environment, where both clean and dirty items are handled.

MicrobeSafe+ is the only antimicrobial additive to be tested to ISO 22196 and JIS Z 2801:2000 standards, demonstrating fast inhibition or elimination of 99.99% of bacteria. Better yet, this protection will remain active for the expected service life of the machine.

The antifungal additive in MicrobeSafe+ also allows surfaces to restrict the build-up of biofilms, as well as unsightly mould growth.

The result? Reliable reduction of the number of bacteria within the medical environment, allowing you to ensure more effective protection against the spread of infection.

Reduced Aerosolisation

The Pulpmatic range of machines have been independently tested and proven to release no aerosolised bacteria[iv] during the maceration cycle. This will give you the confidence that your clinicians and patients are working and recovering in safe environments that aren’t compromised by airborne pathogens.

Smart Chemical Use

We all know that strong chemicals can kill bacteria – however, when and how you use them is often what makes the critical difference to your infection control strategy.

All Pulpmatic macerators feature variable chemical dosing modes, allowing you to choose the most economical and effective way to use your macerator chemicals, including increased dosing when an outbreak of infection occurs.

In addition, the Eco+ macerator features status updates when the chemical is running low, allowing you to ensure that the machine is always well-equipped to work at its optimum.

Specially formulated disinfectants are also available in selected markets.

Pioneering Blockage Prevention & Uptime

DDC Dolphin’s Pulpmatic macerators are specially engineered to minimize build-up of pulp residue within the drainage pipes, delivering a smooth and steady flow of water through the system.

Our one-of-a-kind macerator cycle offers critical innovations, exclusive to DDC Dolphin, which ensure that blockages are prevented and potential maintenance issues are simple to mitigate and resolve.

Open Flow System

Some other macerators on the market are designed to fill with water before each cycle starts.

Large volumes of water and pulp are then discharged to the drain over a short period of time, which can cause overloading and pulp residue build-up. This will soon lead to obstructions.

By contrast, Pulpmatic machines feature open flow maceration during each cycle, promoting the steady flow of wastewater.

Continuous, free flowing maceration technology is kinder to the drains than other forms of ‘dumping’ maceration technology. Only finely macerated, small particles can exit the macerator chamber, resulting in a reduced risk of foreign objects entering the drainage system, as well as minimising furred pipework.

Free Flowing Drainage

Where some other macerators have a one-size-fits-all solution to release water into the drain, we make no assumptions regarding your facility’s drainage capabilities.

DDC Dolphin macerators can be configured to suit complex drainage systems by extending the cycle time to ensure that all macerated waste is flushed away without risk of pipework becoming obstructed.

Foreign Object Catchment System

Pulp macerators are designed to dispose of pulp items only. However, despite best efforts to train staff, it’s inevitable that unsuitable items could find their way into the machine. If allowed to move out of the macerator chamber and into the drains, these foreign objects could cause a major plumbing issue.

A foreign object catchment system is built into each Pulpmatic macerator. A small gap between the upper loading chamber and the lower discharge chamber will ensure that only macerated pulp will pass into the drains.

Other macerators feature ‘dump’ systems which will not accommodate this. They will allow every item from the macerator drum to pass into the drainage system, no matter what it is, resulting in costly plumbing issues.

Advanced Blade System

No Pulpmatic macerator will ever rely on water alone to break down your pulp waste.

We understand that, to prevent blockages and keep your care processes moving, your macerator must pulverise waste to create a fine slurry. That’s why every Pulpmatic features advanced blade technology, so waste can be processed into tiny particles and eliminated through the drain with ease.

The average particle size of pulp macerated by a Pulpmatic macerator is less than 3mm.

Drain Flush

Every Pulpmatic features a self-cleaning drain flush.

An automatic drain flush is programmed during low use times to limit the build-up of stagnant water and remove the possibility of Legionnaires’ disease.

On-Screen Fault Resolution Guidance

Pulpmatic macerators maximise uptime with clear fault guidance, allowing minor maintenance issues – often caused by mis or over-loading of the machine – to be resolved, quickly and easily.

The GUI screen on the Pulpmatic Eco+ offers an enhanced control system. In normal service, the screen will cycle through 3 key screens to indicate the status of a maceration cycle, the items to load in the machine, and the exact error if an issue arises.

For efficient and quick engineering resolution and configuration, an engineer can

access the software menu for adjustment of the machines operating parameters.

Flexible Installation

We want you to benefit from the maceration power of Pulpmatic, exactly where you need it.

Each Pulpmatic is simple to install, with flexible drain heights and positioning to guarantee the best fit for your facility and its individual requirements.

In addition, we offer in-depth Installation Preparation Guides, to help ensure that your site is fully prepared and ready for your new macerator to be installed.

Sluice room servicing is more important now than ever. Discover the reasons why.

Financial Advantages of Pulpmatic Macerators

Managing a healthcare facility responsibly means balancing budgets carefully, while always looking for the most cost-efficient solution – without compromising on quality.

Utility Costs

Pulpmatic macerators are engineered to be as economical as possible, without sacrificing their exceptional levels of performance.

The Pulpmatic Eco+ uses around 13 litres of water per cycle, which is almost 50% less than multi-item machines by other brands. The Vernacare Vortex+, for example, uses 24 litres of water per cycle.

Pulpmatic macerators also excel when it comes to frugal energy consumption. The Pulpmatic Uno, for example, uses just 0.006kWh per cycle.

With 360° Care, you could have a brand-new macerator and a complete maintenance service from just £133 per month. Find out more here.

DDC Dolphin is a specialist sluice/dirty utility room equipment manufacturer and global supplier with 30 years’ experience.

We provide bedpan washer disinfectors, medical pulp macerators and innovative infection control solutions to healthcare facilities around the world.

From the leading technology of our pulp macerators to flushable care wipes and UV air purification systems, we will help your facility to thrive.

Need advice on how best to improve your sluice room and infection control efforts? Contact Our Experts Now

[i] Infection prevention and control, NICE, https://www.nice.org.uk/guidance/qs61/chapter/introduction

[ii] World Health Organization, Health Care Associated Infections Fact Sheet, https://www.who.int/gpsc/country_work/gpsc_ccisc_fact_sheet_en.pdf

[iii] Examination of cross contamination risks between hospitals by external medical staff via cross-sectional intercept survey of hand hygiene, Hank Schiffers, Sarah Zaatreh, Wolfram Mittelmeier, and Rainer Bader, https://www.ncbi.nlm.nih.gov/pmc/articles/PMC4141635/#R1

[iv] There is currently no formal standard for the determination of aerosols from Medical Macerators,

therefore, the following study was developed in conjunction with DDC Dolphin Ltd using

standard microbiological techniques and utilising guidance from ISO 15883-1 : 2009/A1 : 2014

(Ref 3), ISO 15883-5: 2021, and adapting the methodology described in the Environment

Agency Document - Healthcare Waste: Appropriate Measures for Permitted Facilities (July

2020)